Steel Spiral Tubing For Ventilation Systems

Ventilate your mines, tunnels and shafts with Roladuct

Roladuct Steel Spiral Tubing for the ventilation (supply or exhaust) of mines, tunnels and shafts can be used as a temporary vent line during construction or as a permanent installation.

The tubing is machine made using a 4 ply lock seam, running helically around the outside of the tube, giving a very smooth and efficient interior suface. For circumferential strength, corrugations are formed between the spiral seams during the manufacturing process, these corrugations aid in resisting collapse of the duct from abnormal negative pressures or accidental damage from other equipment in use.

The tubing is normally made from a coated (zinc or paint) mild steel strip, but other materials such as uncoated mild steel, stainless steel or aluminium can be used.

Specifications

Round Duct Diameters:

75mm to 3000mm

Oval Duct Sizes:

150mm x 500mm to 700mm x 1950mm

Material Thickness:

0.5mm to 3.0mm (oval maximum 1.2mm)

Duct Length:

Any length up to 12 metres, standard recommended length is 3 metres.

Fittings

Refer Roladuct General Range of Fittings

Note: Material thickness per diameter can be selected and recommended by Roladuct to suit your specification of negative or positive pressures. We have conducted many tests in this regard as guidelines for efficient pricing.

Joining Methods

- Slip Joint - Extra Long Leading Edge - Safe Egde (300mm long)

300mm wide re-usable Rubber Duct Bands

300mm wide re-usable Rubber Duct Bands - Flanged Joint

Sizes of Angle Flange (with rubber gasket) to suit diameter.

Sizes of Angle Flange (with rubber gasket) to suit diameter.

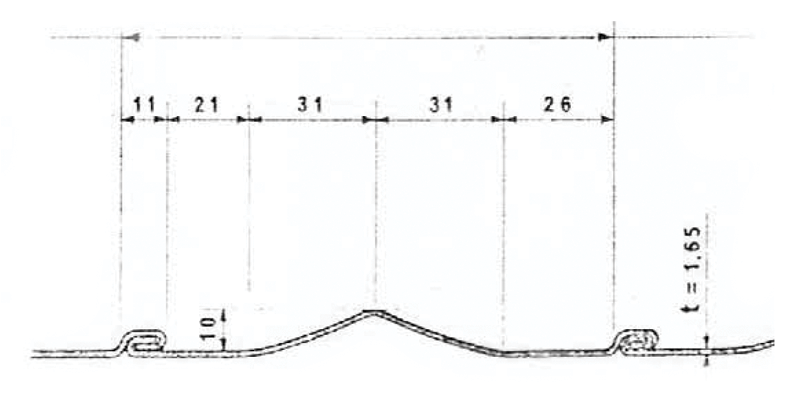

Corrugation Profile

| Standard diameter | Thickness | Weight |

|---|---|---|

| 600mm | 0.8mm | 16kg/m |

| 750mm | 0.8mm | 20kg/m |

| 450mm | 0.8mm | 12kg/m |

| 900mm | 1.0mm | 29kg/m |

| 1000mm | 1.0mm | 33kg/m |

| 1200mm | 1.2mm | 52kg/m |

| 1400mm | 1.6mm | 76kg/m |

| 1800mm | 1.6mm | 98kg/m |